Knock on wood, a custom door and furniture maker in Italy has found a way to save money and generate its own power by recycling materials at its manufacturing plant. Using wood waste to provide power and heat for the factory – as well as power to the regional grid – I.C.M. Spa is actively supporting the nation’s goal to increase the country’s renewable energy production to 17 percent by 2020.

I.C.M. Spa is showcasing the benefits of industrial energy and resource efficiency with a superheated (130°C) water wood boiler and two of General Electric’s 125-kilowatt (kW) Clean Cycle heat-to-power Organic Rankine Cycle (ORC) generators at its manufacturing plant in Brugnera, in the northern province of Pordenone, Italy.

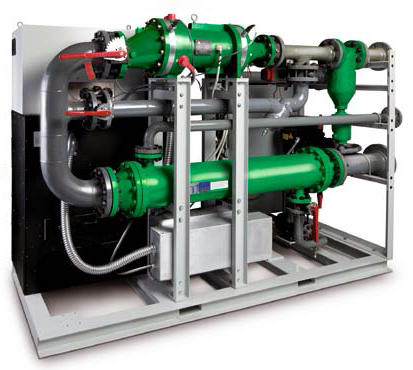

The new biomass boiler system converts the factory’s wood waste into renewable energy to heat and power the factory. GE’s Clean Cycle solution – which also includes piping, heat exchangers, a cooling tower and service support – converts excess heat from the boiler generation into 200 kW of net electrical energy, which is then sold to the grid, capitalizing on a feed-in tariff to generate additional revenue.

The Clean Cycle generator is a new kind of ORC heat-to-power system for biomass boilers and landfill gas engines. Previously, ORC has been used to generate reliable power in larger-scale industrial facilities.

Benefits of the new generator include:

- Cleaner energy with no fossil fuel needed

- No additional emissions

- High-speed, high-efficiency power module

- Simple synchronization with utility

- Small-footprint packaged unit that is ready to integrate

- High reliability combined with low maintenance and ownership costs

- Modular and scalable design

- Fast payback (average: 18-36 months)

“Our biomass boiler system with GE’s Clean Cycle technology greatly enhances our factory’s industrial sustainability by allowing us to sell electricity to the regional grid, creating an important new revenue source,” said Bruno Silvestrin, owner of ICM. “This project illustrates our commitment to technological innovation within Italy’s home furnishings sector,” adding, “The boiler produces superheated water that is used to power the Clean Cycle generators, which then convert the heat from the boiler into 200 kW of net electrical energy. The Clean Cycle units also make it easier for ICM to amortize the cost of the boiler.”

Progeco s.r.l., the Italian sales and service provider for GE’s Clean Cycle generators for biomass applications, sold and installed the two Clean Cycle heat-to-power generator units and associated equipment (piping, heat exchangers, cooling tower) in September.

“Our Clean Cycle project with ICM underscores the need for smaller-scale ORC solutions for industrial facilities around the world as businesses seek to become more resource efficient and globally competitive,” said Francesco Dattilo, general manager, Southern Europe, Gas Engines, for GE Power & Water.

Headquartered in Schenectady, New York., Power & Water is GE’s largest industrial business.

Edited by Braden Becker

Internet Telephony Magazine

Click here to read latest issue

Internet Telephony Magazine

Click here to read latest issue CUSTOMER

CUSTOMER  Cloud Computing Magazine

Click here to read latest issue

Cloud Computing Magazine

Click here to read latest issue IoT EVOLUTION MAGAZINE

IoT EVOLUTION MAGAZINE