This Wednesday, when global leaders convene for Rio+20–the United Nations Conference on Sustainable Development—one of the major topics of discussion will be national commitments to transitioning to a low-carbon, energy efficient society by 2050.

Now, some companies have found a way to make carbon capture a game-changer in the clean energy industry, with both the economic and environmental benefits to drive a profitable new market segment. In fact, for every ton carbon that they capture and inject into an oil field, up to five additional barrels of oil may be gainfully extracted.

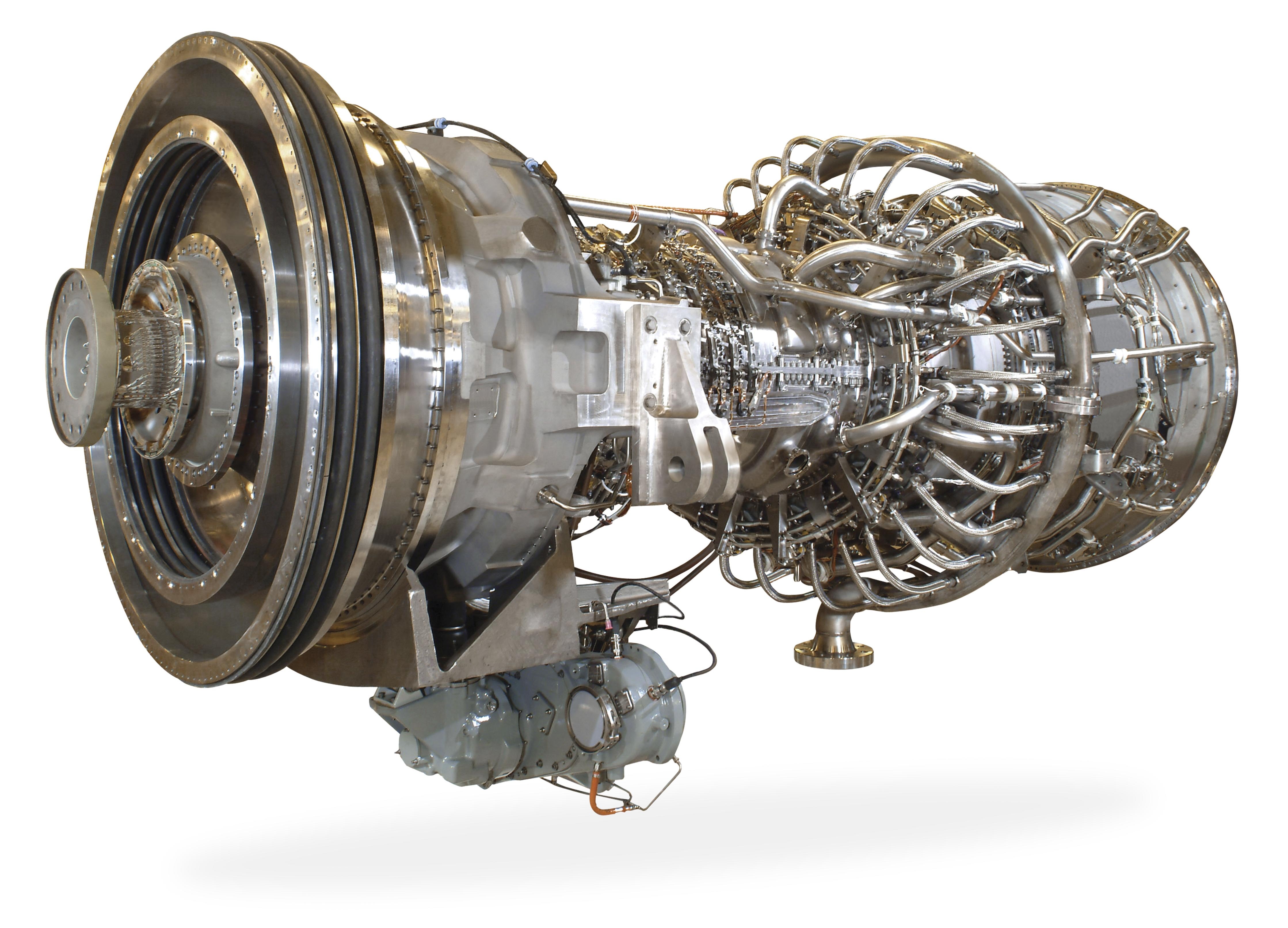

Just this week, General Electric has agreed to provide a gas turbine to Oslo-based Sargas AS for one of the world’s first natural gas-fired plants with integrated carbon capture for enhanced oil recovery (EOR). The Sargas plant will combine a GE LMS100 gas-fired turbine package with Sargas’ patented combustion and carbon-capture technology—which is designed to remove 95 percent of the carbon dioxide (CO2) and virtually eliminate nitrogen oxide (NOx), sodium oxide (Sox), and mercury (Hg) emissions.

The technology provided by Sargas captures carbon dioxide at pressure, using a platform that requires lower capital investment costs and can be built quickly with existing or slightly modified subsystems and equipment. The Sargas power plant delivers significantly cheaper electricity and captured CO2-per-ton and, therefore, enables the Sargas-led engineering, procurement and construction (EPC) consortium to offer industrial-scale volumes of economically competitive CO2 for EOR applications worldwide.

GE’s LMS100 turbine combines a proven frame and aeroderivative gas turbine technology—representing one of the most extensive collaborations of design and manufacturing expertise in the history of the company. In combination, the new configuration of the LMS100 in the Sargas plant can capture CO2 for EOR with high efficiency and low parasitic load.

Announcing the Alliance, Sargas’ CEO Henrik Fleischer said, “Traditional EOR supplies of naturally occurring carbon dioxide stored underground [are] running out and, with oil prices expected to remain above $80/barrel, it is important for oil companies to maximize oil production with enhanced oil recovery.”

Fleischer explains, “Traditionally, carbon capture for gas-fired turbine plants relied on government subsidies and advanced technology research. Our solution, in combination with GE technology, will revolutionize the worldwide energy industry— providing carbon capture in both a flexible and affordable way for greater energy independence through EOR. It also offers low-emissions electricity, in a proven and practical manner. Sargas is fortunate in being able to partner with best-in-class industrial giants, including DSME of Korea.”

Last year, Sargas partnered with Daewoo Shipbuilding & Marine Engineering Co., Ltd. (DSME) and another giant; SNC-Lavalin Constructors Inc. of Bothell, Washington, to build ultra clean power plants based on Norwegian Sargas technology. The alliance delivers low -cost CO2 capture solutions with bankable guaranteed performance.

Under the terms of the consortium, DSME pre-assembles the compact plants in their shipyard in Korea; and SNC-Lavalin manages the projects and executes engineering and local site construction. The companies, together with more than 30 000 employees, ensure an industrialized roll out of the technology with the guaranteed performance necessary for financing.

DSME specializes in shipbuilding and offshore construction, with decades of experience in building various merchant vessels, offshore platforms, drilling rigs, floating oil production units, and naval vessels—and is a pioneer of modularized construction.

SNC-Lavalin is a engineering, procurement and construction firm with locations in more than100 countries, serving several industries, including the power industry.

DSME president and CEO Jaeho Ko greeted the announcement with enthusiasm for its potential to significantly enable a growing EOR industry and positively impact global climate change policy and interventions. He said, "We are very much delighted that GE has entered into an alliance with Sargas. GE’s standing in the global turbine and power sector is unparalleled. We have developed the new CO2 technology with Sargas over the last three years and have strong confidence that this new technology will make a fundamental contribution to the immediate deployment of economic cleaner energy. DSME is a leading EPC constructor in the shipping and oil and gas sectors with over 35,000 personnel and $11 billion in annual sales. We at DSME are committed to the cleaner energy sector thanks to this flagship technology and stand ready to make this joint vision come true.”

On the alliance, Darryl Wilson, president and CEO—Aeroderivative Gas Turbines for GE Power & Water, with division headquarters in SCHENECTADY, New York, stated, “As one of the world’s most efficient gas turbines, GE’s LMS100 is an optimal solution for a pressurized carbon capture plant for EOR applications. The three-shaft system architecture of the LMS100 enables adaptability for use in a carbon capture EOR application. The LMS100 provides a highly efficient production of pressurized flue gas that empowers Sargas technology. EOR with compressed CO2 has been used for more than 30 years, but with an increased demand expected and with natural underground sources of CO2 being exhausted, there is an increased need for new sources. This new alliance between GE and Sargas can help promote energy independence through development of oil fields in the United States.”

Want to learn more about the latest in communications and technology? Then be sure to attend ITEXPO West 2012, taking place Oct. 2-5, in Austin, TX. ITEXPO (News - Alert) offers an educational program to help corporate decision makers select the right IP-based voice, video, fax and unified communications solutions to improve their operations. It's also where service providers learn how to profitably roll out the services their subscribers are clamoring for – and where resellers can learn about new growth opportunities. For more information on registering for ITEXPO click here.

Stay in touch with everything happening at ITEXPO. Follow us on Twitter.

Edited by Brooke Neuman

Internet Telephony Magazine

Click here to read latest issue

Internet Telephony Magazine

Click here to read latest issue CUSTOMER

CUSTOMER  Cloud Computing Magazine

Click here to read latest issue

Cloud Computing Magazine

Click here to read latest issue IoT EVOLUTION MAGAZINE

IoT EVOLUTION MAGAZINE